Last Updated on February 9, 2023

Sewing can be a tricky craft to master, and there’s no doubt that the right tools make all the difference. One of those essential tools is the presser foot on your sewing machine – but what is a presser foot on a sewing machine? And how do you know which one to use for each project? If you’ve ever been confused by this important part of your machine, don’t worry: we’re here with all the info about a presser foot on a sewing machine so you can get started. In this blog post, we’ll explore what types of presser feet are available; how to change them out quickly; the benefits they offer when used correctly; and troubleshooting tips if things go wrong. So grab some thread, and let’s dive in.

Table of Contents:

What is a Presser Foot?

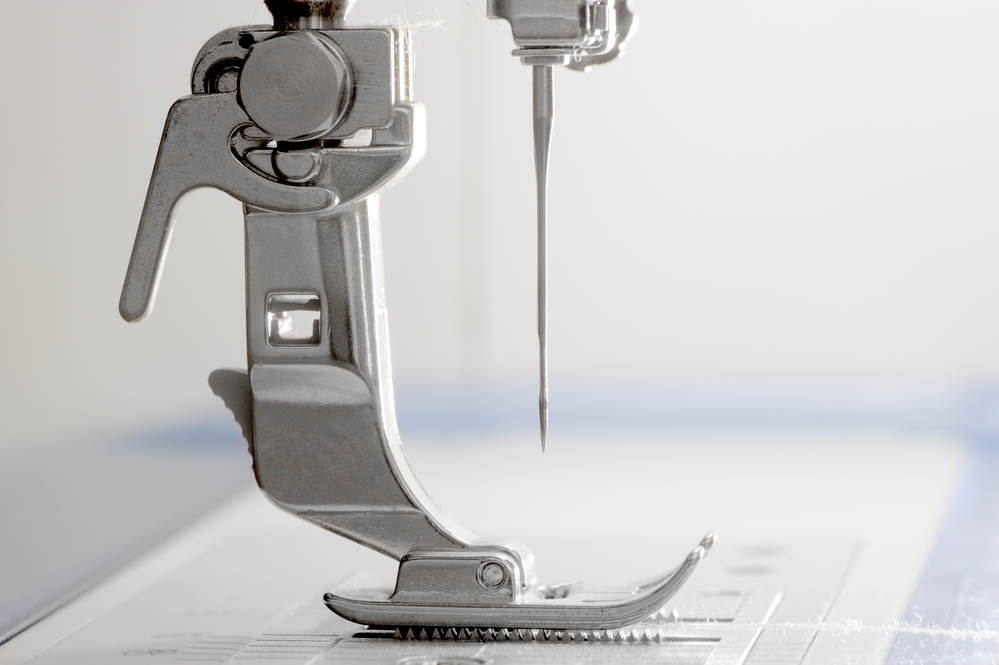

A presser foot is an attachment for a sewing machine that holds the fabric in place as it moves through the machine. It works by pressing down on the fabric and guiding it along, allowing you to sew with precision and accuracy. The most common type of presser foot is the zigzag or straight stitch foot, which has two metal prongs that hold onto either side of your fabric as you sew.

There are many different types of presser feet available for purchase, depending on what kind of project you’re working on. A walking foot, for example, helps keep multiple layers of fabric from shifting while being sewn together. Other popular presser feet include blind hem feet, buttonhole feet, piping/cording feet and quilting/darning feet.

To change out a presser foot, first, loosen the screw located at the back of your sewing machine near where your needle is situated. Then, lift up on the lever arm until it releases its grip on your current presser foot so that you can remove it from underneath your needle plate area before replacing it with another one if necessary or desired.

Utilizing a presser foot provides various advantages when compared to hand-sewing projects, such as faster outcomes due to less time spent manually manipulating fabrics; more precise stitching lines since they assist in guiding fabrics into place; greater uniformity between stitches because each pass will appear identical; and improved manoeuvrability around tight corners or difficult areas like pockets or pleats thanks to their adjustable pressure settings.

A presser foot is an essential part of a sewing machine. It’s the metal plate that holds your fabric in place while you sew. The presser foot has two main functions: it keeps the fabric from moving around as you stitch, and it helps guide the needle through the fabric.

Presser feet come in many shapes and sizes to accommodate different types of fabrics and techniques. For example, there are zigzag feet for decorative stitching, buttonhole feet for making buttonholes, quilting feet for piecing together patchwork quilts, and overlock/serger feet for finishing edges with a neat seam allowance.

To attach a presser foot to your machine, simply lower the lever on top of your machine until it clicks into place. This will release the old presser foot so you can remove it and replace it with another one. Some machines have snap-on or screw-on presser feet, which make changing them even easier.

When using a straight stitch setting on your sewing machine, it is important to note that the majority of standard presser feet do not possess any additional features such as feed dogs or guides, which would assist in keeping stitches even and consistent with regard to width. Therefore, some individuals opt for an adjustable zipper/edge guide instead when they need more precision over their stitching line’s accuracy.

The pressure applied by the presser foot also affects how well stitches form; too much pressure can cause puckering or skipped stitches, whereas not enough pressure may result in uneven seams or missed stitches altogether. To adjust this tension correctly on most machines, just turn either knob located near where the thread passes through tension discs until desired results are achieved – but be sure not to go too far otherwise, you’ll end up having problems again.

Types of Presser Feet

They help to hold the fabric in place and guide it through the needle as you sew. There are many different types of presser feet available, each designed for a specific purpose.

The most common type is the all-purpose foot, which can be used for basic stitching on a variety of fabrics. This foot has a flat bottom with two grooves that fit over the needle plate and keep your fabric from slipping while you sew. It’s also adjustable, so you can raise or lower it depending on what kind of stitch you want to make.

If you need more control when sewing curves or corners, then an edge-stitching foot might be right for you. This presser foot has a narrow groove along its underside that helps guide your stitches around curves without puckering or stretching out the fabric too much.

A zipper foot is another useful tool if you plan on doing any zippered projects like bags or pillow covers. The side of this presser foot is cut away so that it fits snugly against one side of the zipper teeth as you sew them together, giving better visibility and accuracy than other types of feet would provide.

For quilting projects, there’s nothing better than using a walking foot attachment on your machine; this will ensure even feeding from both sides as well as help to reduce bulkiness in multiple layers of fabric at once. A free motion quilting attachment works similarly but allows greater freedom when stitching intricate designs into quilts or garments since it moves independently from your hands instead of being guided by feed dogs beneath the work surface as other attachments do.

Finally, hemming often requires specialized tools such as blind hemming feet, which have small hooks along their undersides that catch onto folded edges and help create neat hems without having to pin everything first.

There are many types of presser feet available, each with its own unique function. Now let’s take a look at how to change the presser foot on your sewing machine.

Benefits of Using a Presser Foot

Using a presser foot when sewing can be incredibly beneficial. It helps to ensure accuracy and precision in your work, as the presser foot holds the fabric in place while you sew. This makes it easier to keep seams straight and even, which is especially important for quilting projects or garments that require precise measurements. Additionally, using a presser foot allows you to sew faster than if you were not using one. By keeping the fabric taut against the feed dogs of your machine, it eliminates any slipping or shifting that could slow down your progress.

A presser foot can also come with various attachments, depending on the type of stitch you are doing. An adjustable zipper foot makes installing zippers easy without having to reposition the needle; a blind hemming foot allows for creating invisible hems quickly and effortlessly, while a gathering foot adds volume to fabrics by distributing even gathers as they’re sewn into place. With these specialized tools available, producing professional-looking results becomes much more manageable.

In addition to its practical benefits, using a presser foot can also help make sewing more enjoyable overall by reducing fatigue from constantly adjusting fabric while working on larger projects like quilts or curtains. The extra support provided by this tool means less strain on your hands and arms so that stitching remains comfortable throughout longer sessions at the machine—a definite plus.

Finally, many modern machines come with built-in features such as automatic thread cutting and reverse stitching capabilities that are designed specifically for use with certain types of presser feet (such as those used for buttonholes). These functions can save time during tedious tasks like topstitching buttons onto garments or making neat rows of stitches across large pieces of material, allowing crafters to focus their energy elsewhere instead.

Using a presser foot can make sewing projects much easier and more efficient. With the right troubleshooting tips, you can maximize the potential of your presser foot and get great results every time.

Conclusion

In conclusion, a presser foot on a sewing machine is an essential tool for any sewer. It helps to hold the fabric in place while you sew and can be used with different types of fabrics and stitches. Changing your presser foot is easy once you know how, and there are many benefits to using one. If you ever experience problems with your presser foot, some troubleshooting tips should help get it back up and running again. With all these advantages, having a presser foot on your sewing machine is definitely worth considering.

Paul is the type of person who never met a problem he couldn’t fix. He can always be found tinkering with something in his house, even if it isn’t broken! His tips and tricks are often shared on our site. He’s the one you call when something breaks because he has been known to improvise fixes for everything from leaky faucets to malfunctioning dryers.